German RepRap (now innovatiQ) 3D printer assists in development of BICAR

The Center for Product and Process Development (ZPP) at ZHAW in Zurich specializes in innovative product development in mechanical engineering from the initial idea to the final series production…

Zurich Opera House relies on 3D printers from innovatiQ for props and mold making.

With 12 new productions on the main stage every year, numerous revivals, concerts, song recitals, a wide range of young talent programs and over 300 performances, Zurich Opera House is the largest…

Additive manufacturing with the x500 for customized ride comfort

The company also benefits from new possibilities in terms of materials and design thanks to the wide range of customization solutions. Most current mid- or luxury-class vehicle models fascinate with…

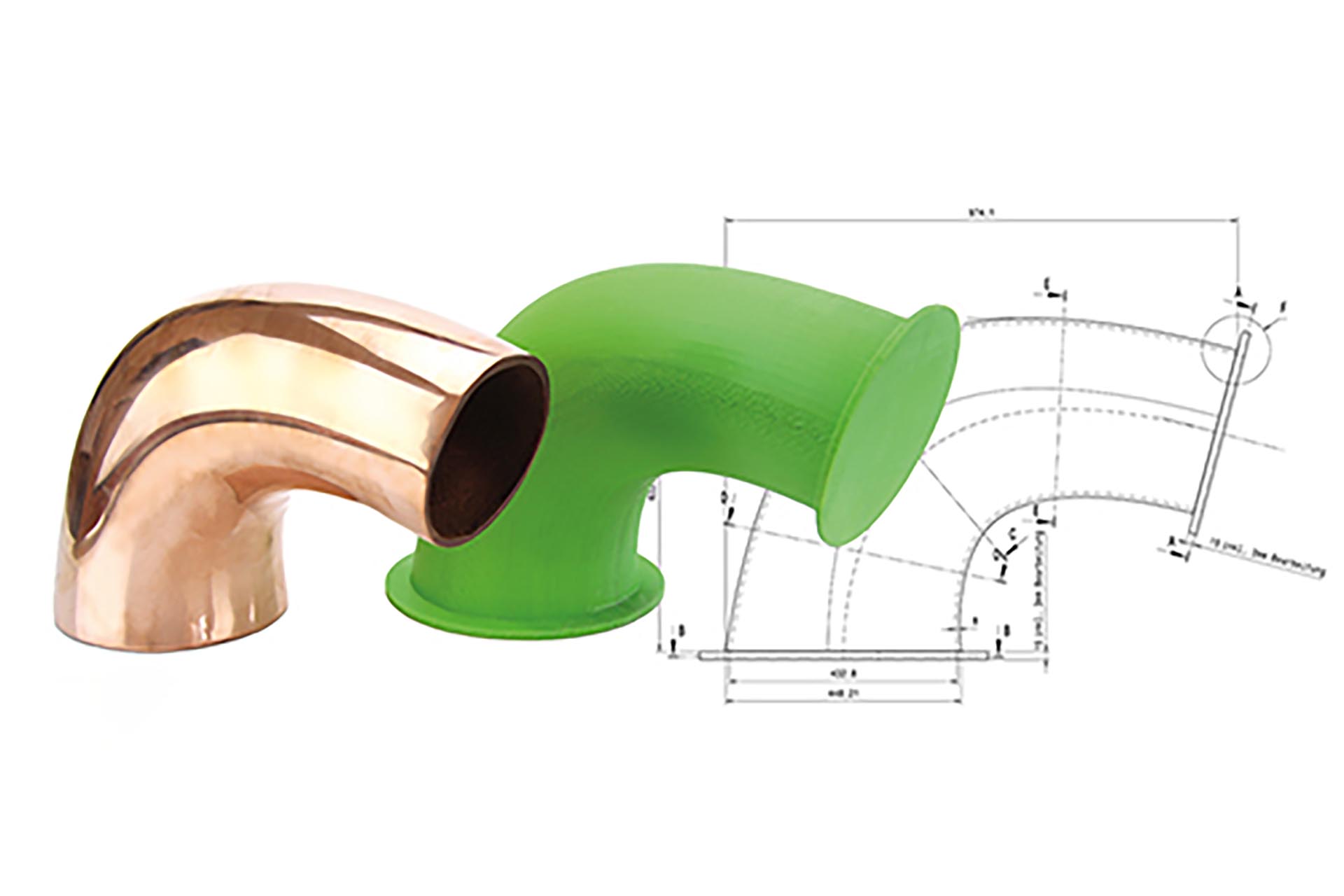

Casting core from the 3D printer - Carl GmbH reduces manufacturing costs

An x400 3D printer reduces manufacturing costs at distillery equipment manufacturer Carl GmbH. Carl GmbH has been manufacturing distillery, distillation and brewery equipment for more than 140 years.…