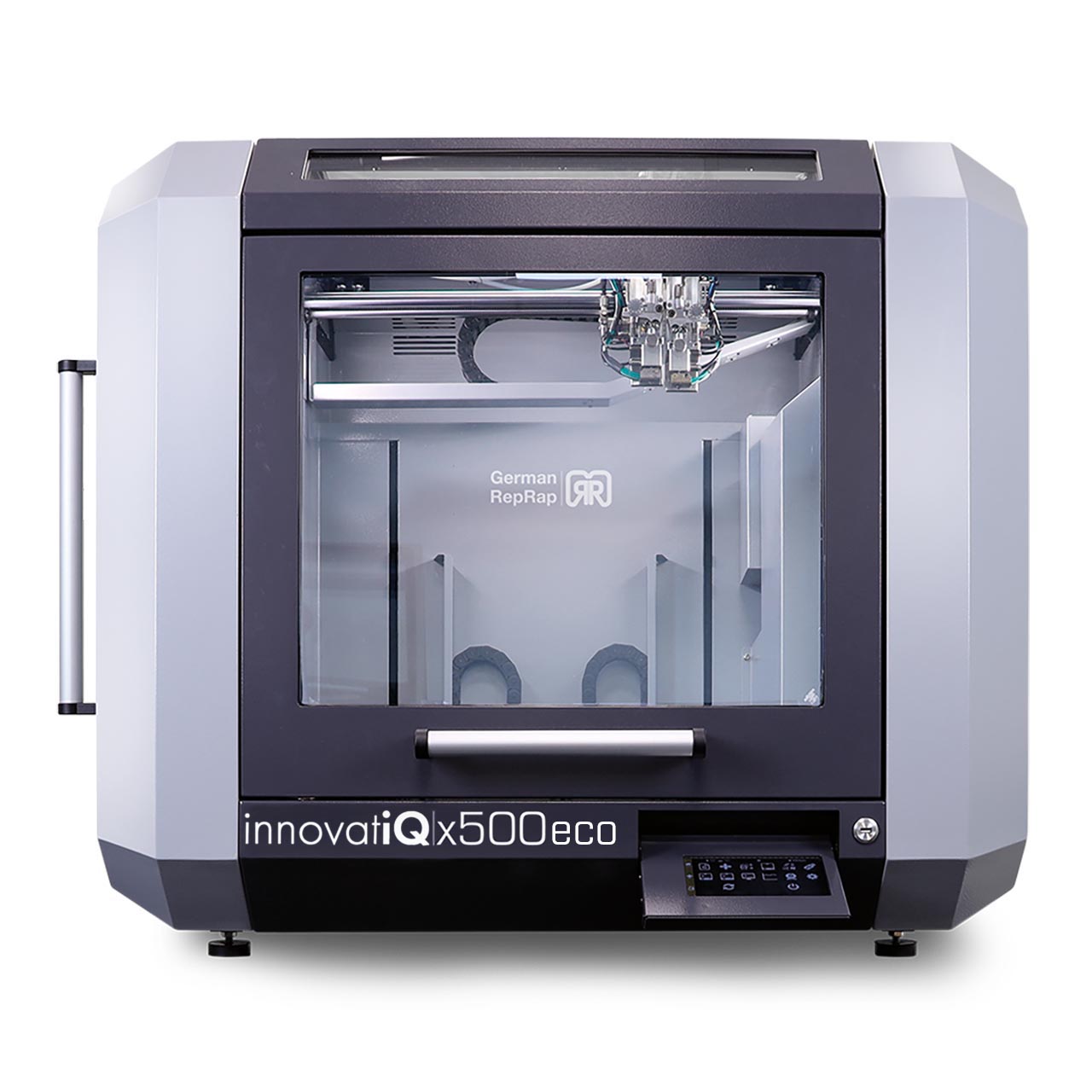

The x500eco – Economical entry into industrial 3D printing.

The x500eco is the solution for printing high-performance, high-temperature and abrasive materials. The open material system guarantees the use of a wide variety of materials without tied to a specific manufacturer.

The permanent, sensor-controlled measurement of the filament feed ensures reliable precision and process reliability in 3D printing. The fully automatic leveling of the printing plate at every system start guarantees a quick start of the next print job.

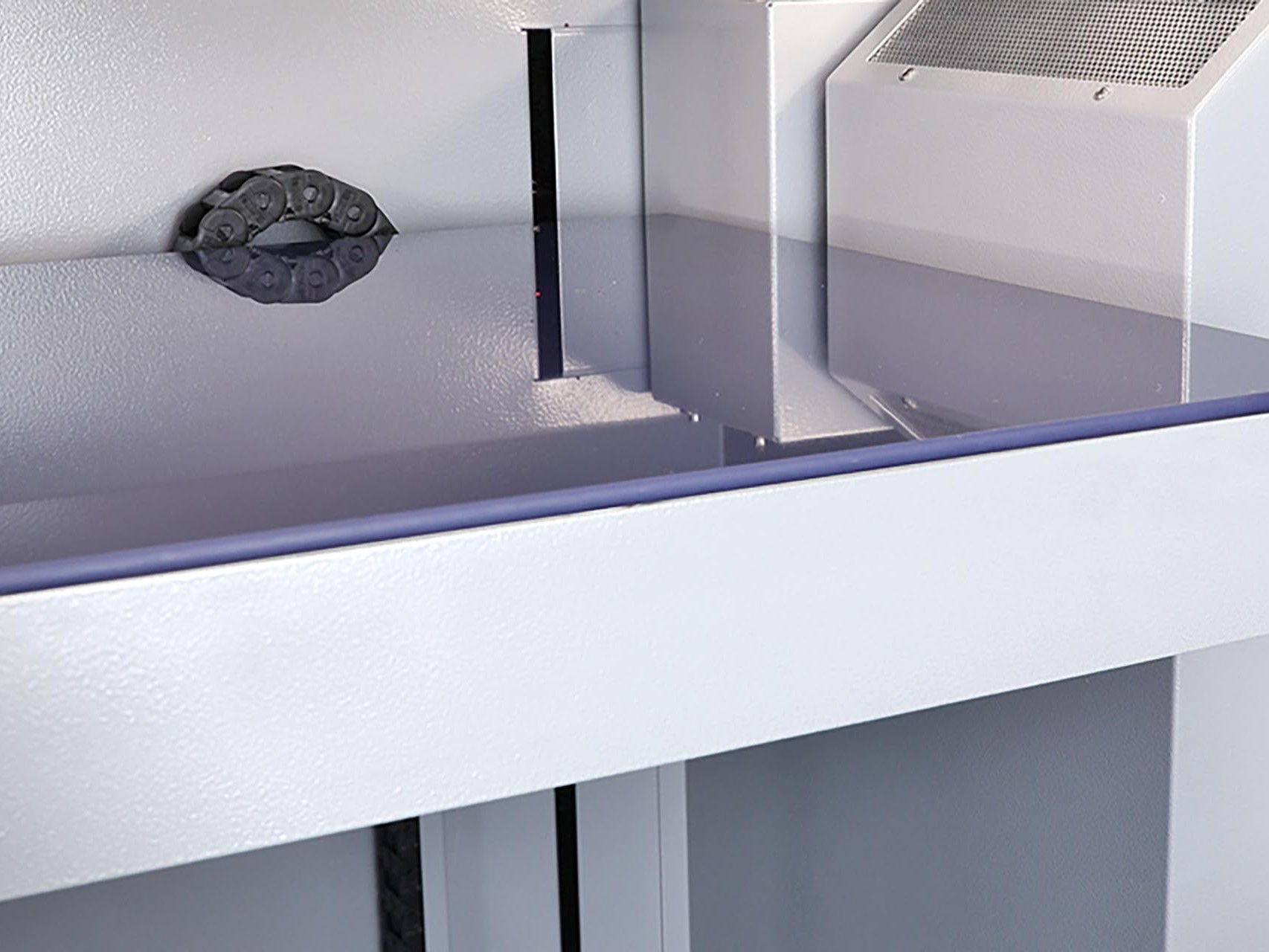

With an installation space volume of 90 liters in the dimensions 500 x 400 x 450 (X/Y/Z) millimeters, it is one of the largest in its class.

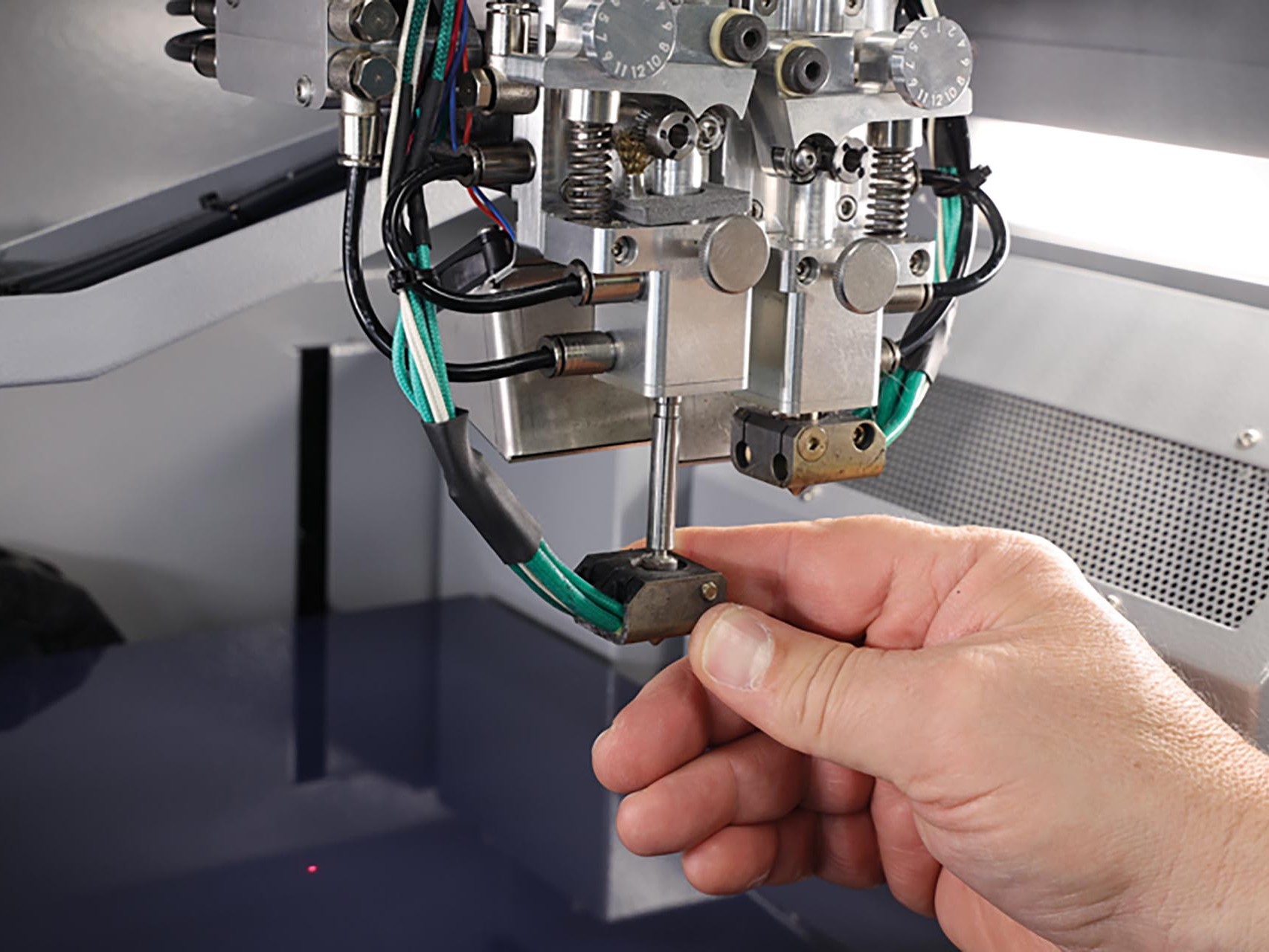

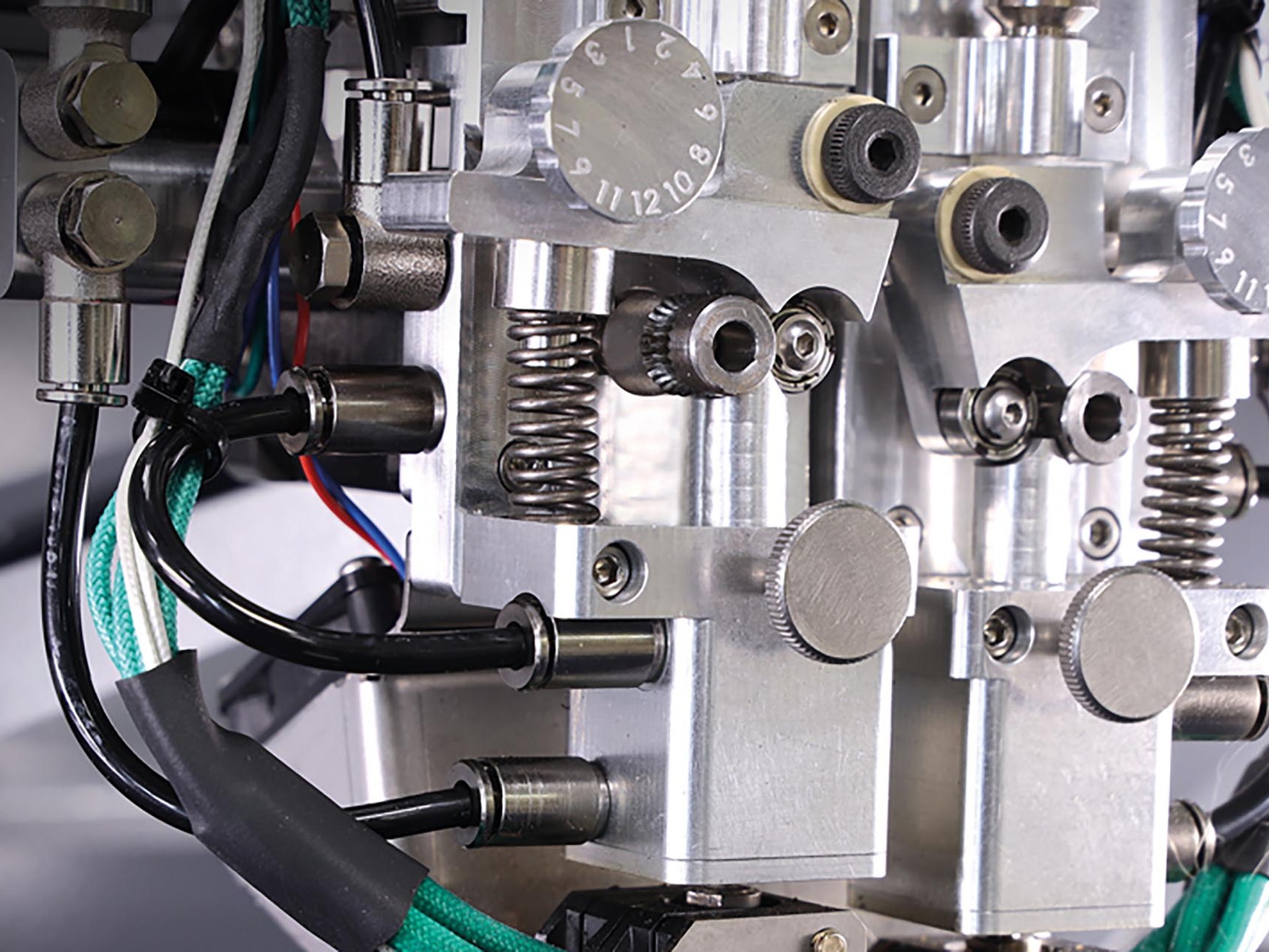

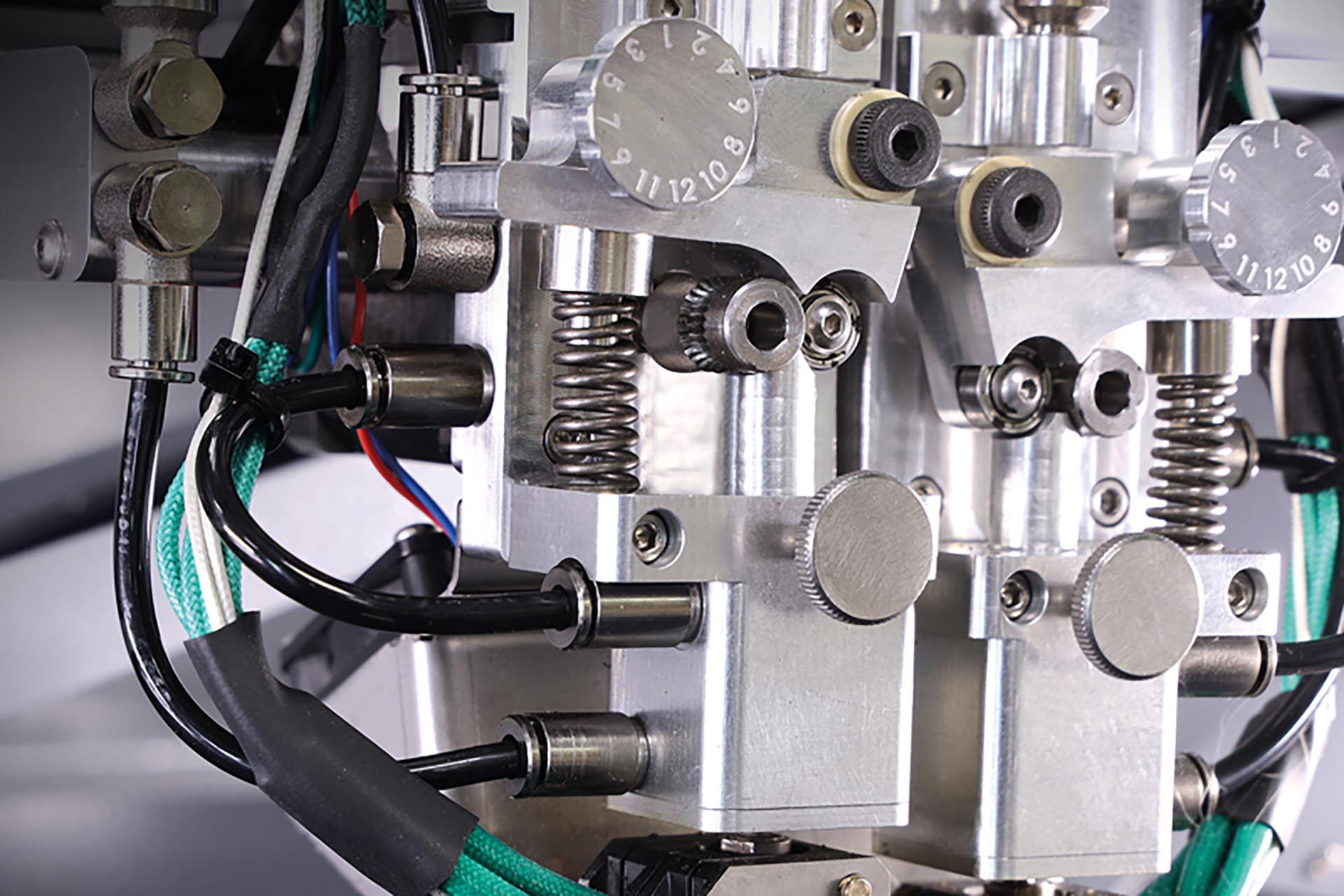

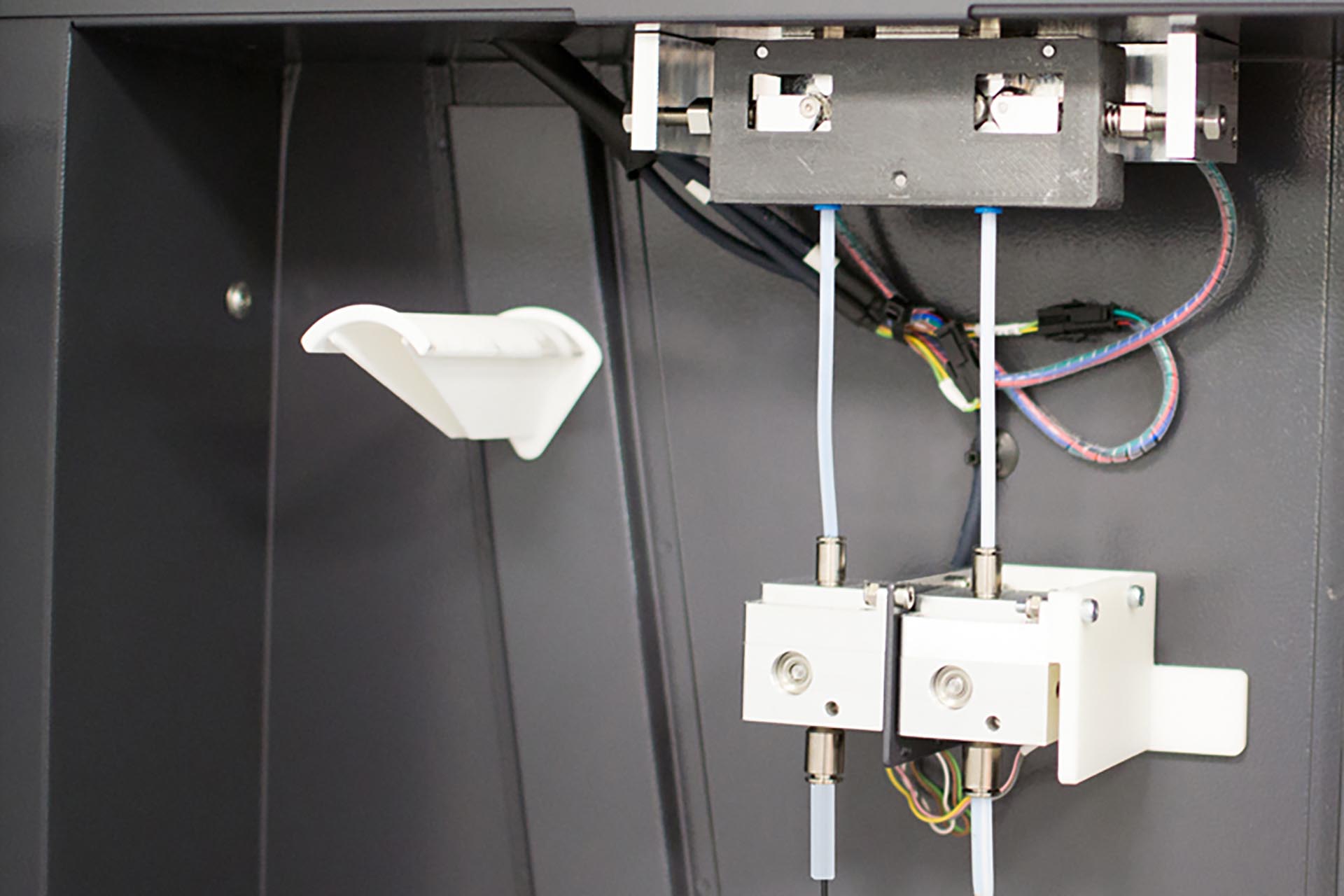

- SmartTrack: Permanent, sensor-controlled measurement of filament feed

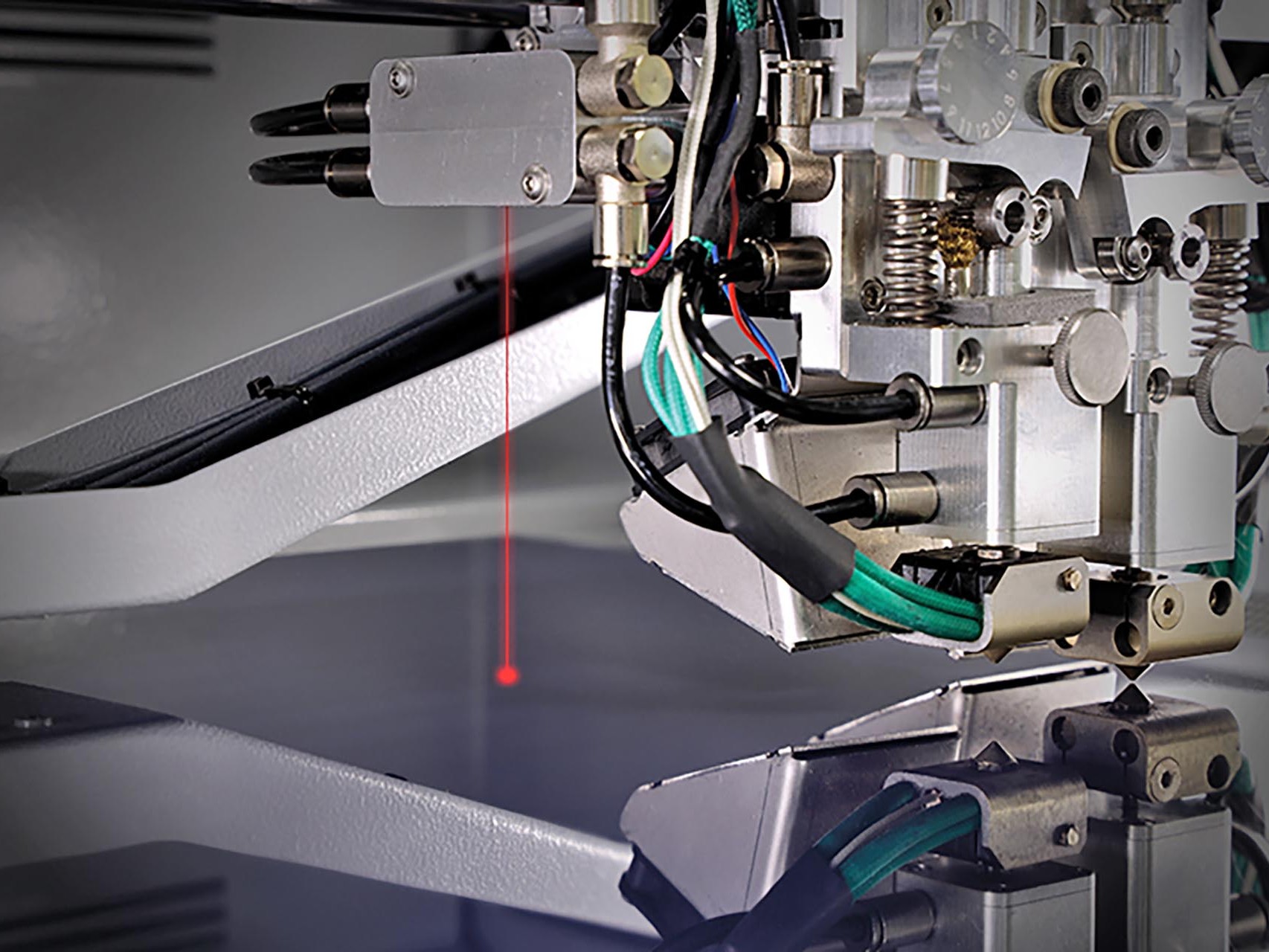

- SmartStart: Fully automatic leveling of the printing plate

- Open control system (Arduino)

- Processing of demanding materials such as PC, PA, PA Carbon, ABS

- Open material system

Technical features

The large installation space of the x500eco is optimized for the production of components in continuous industrial operation.

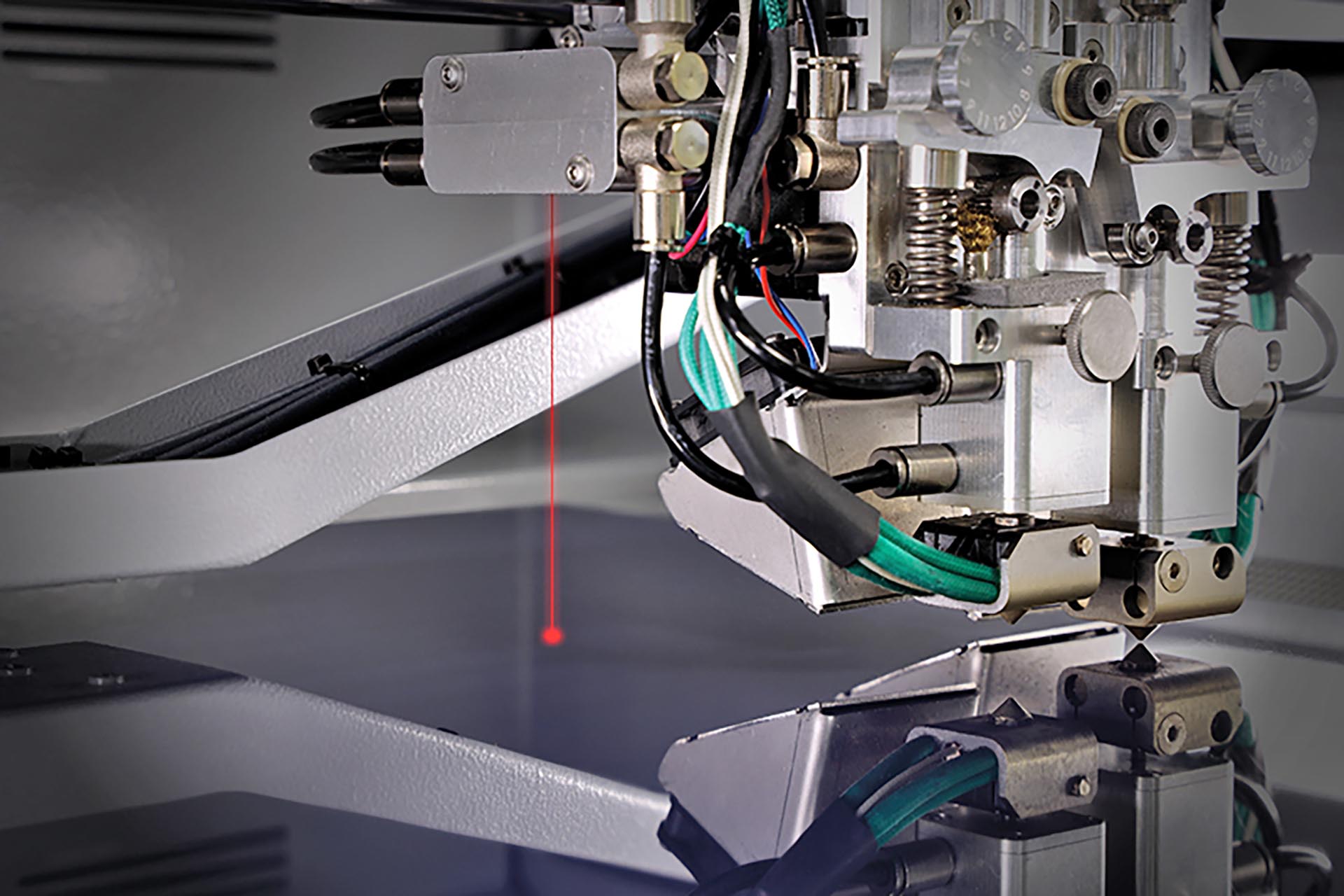

SmartStart: Laser-assisted print bed leveling ensures optimum adjustment of the print bed.

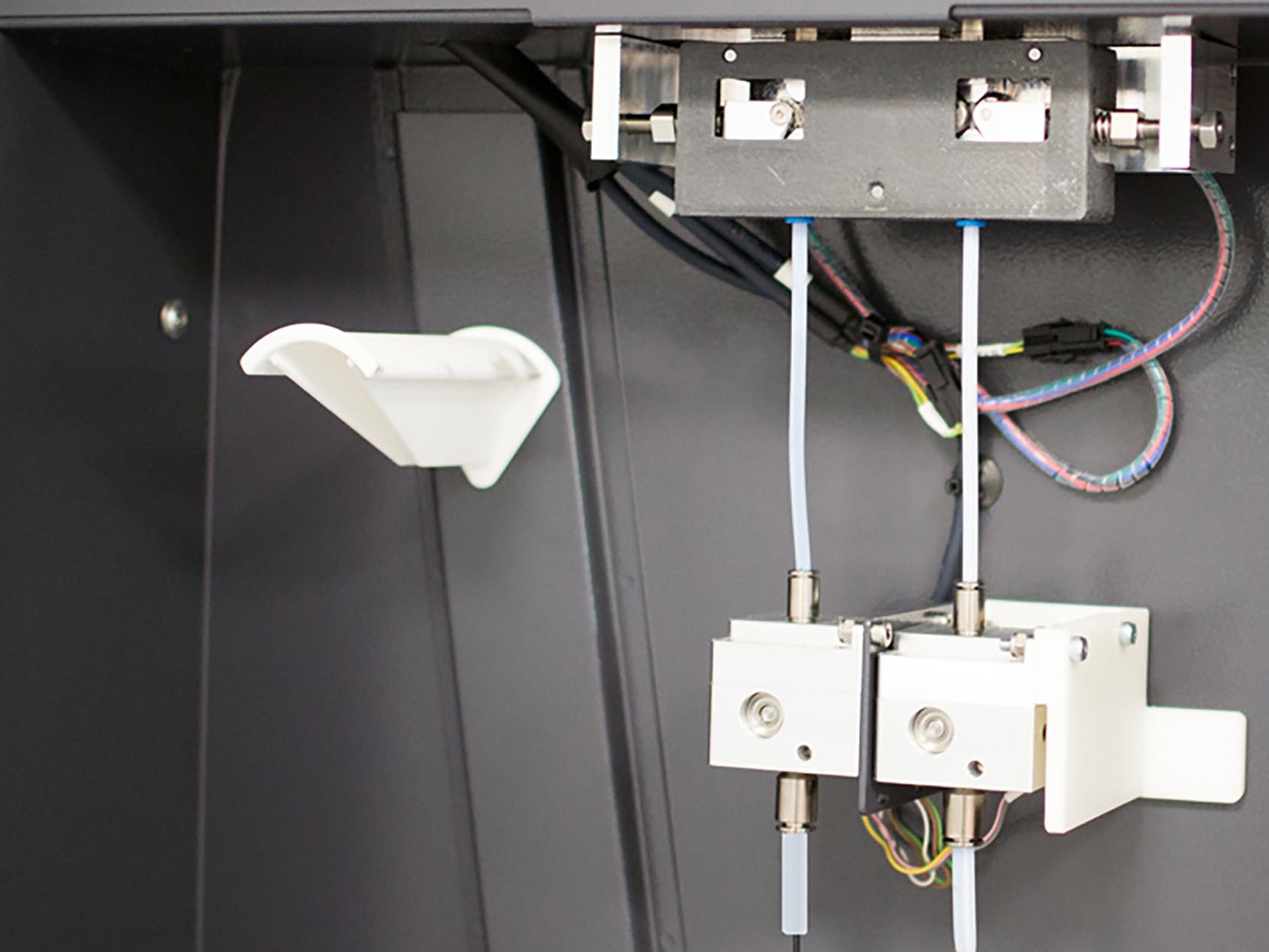

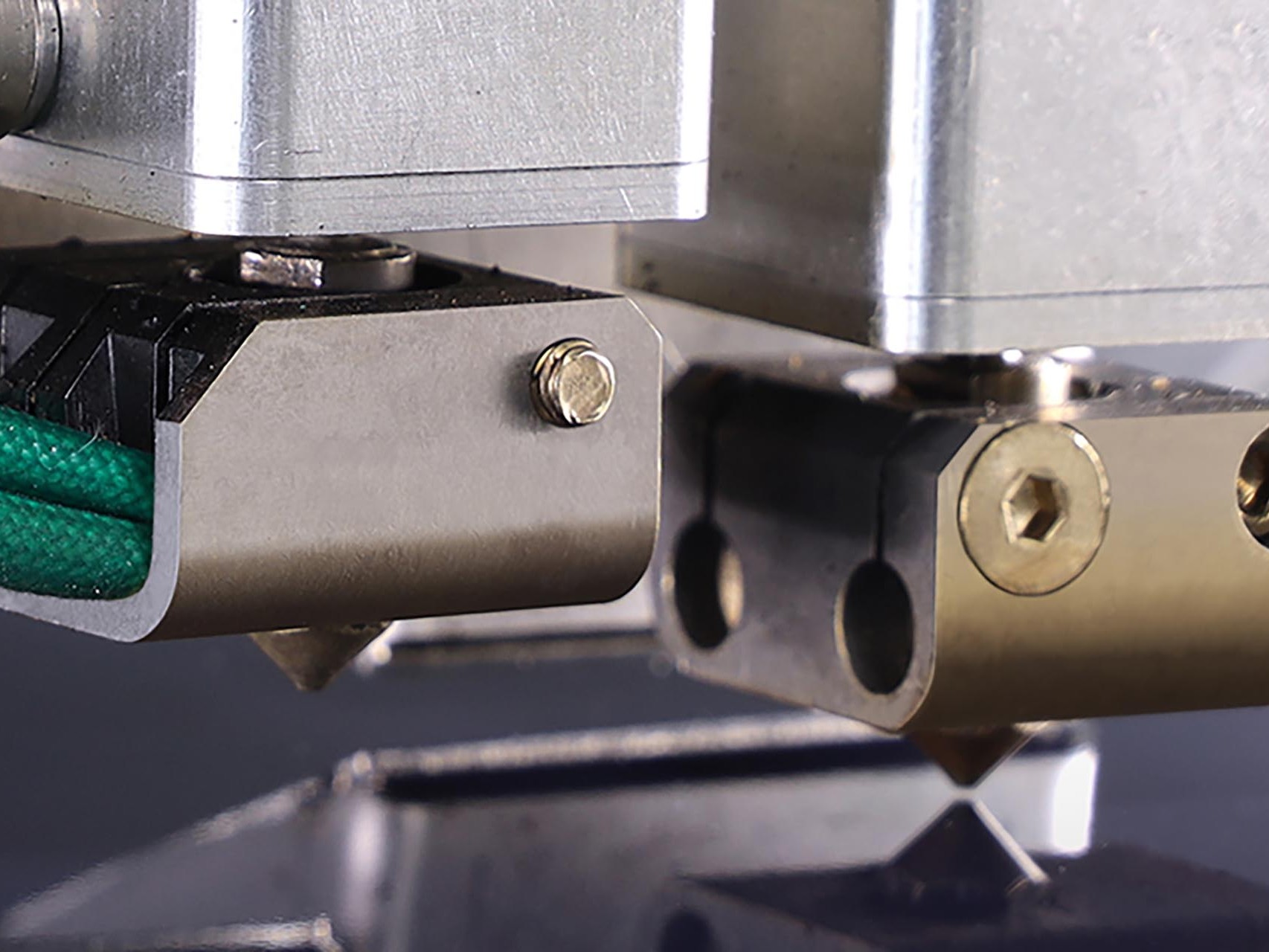

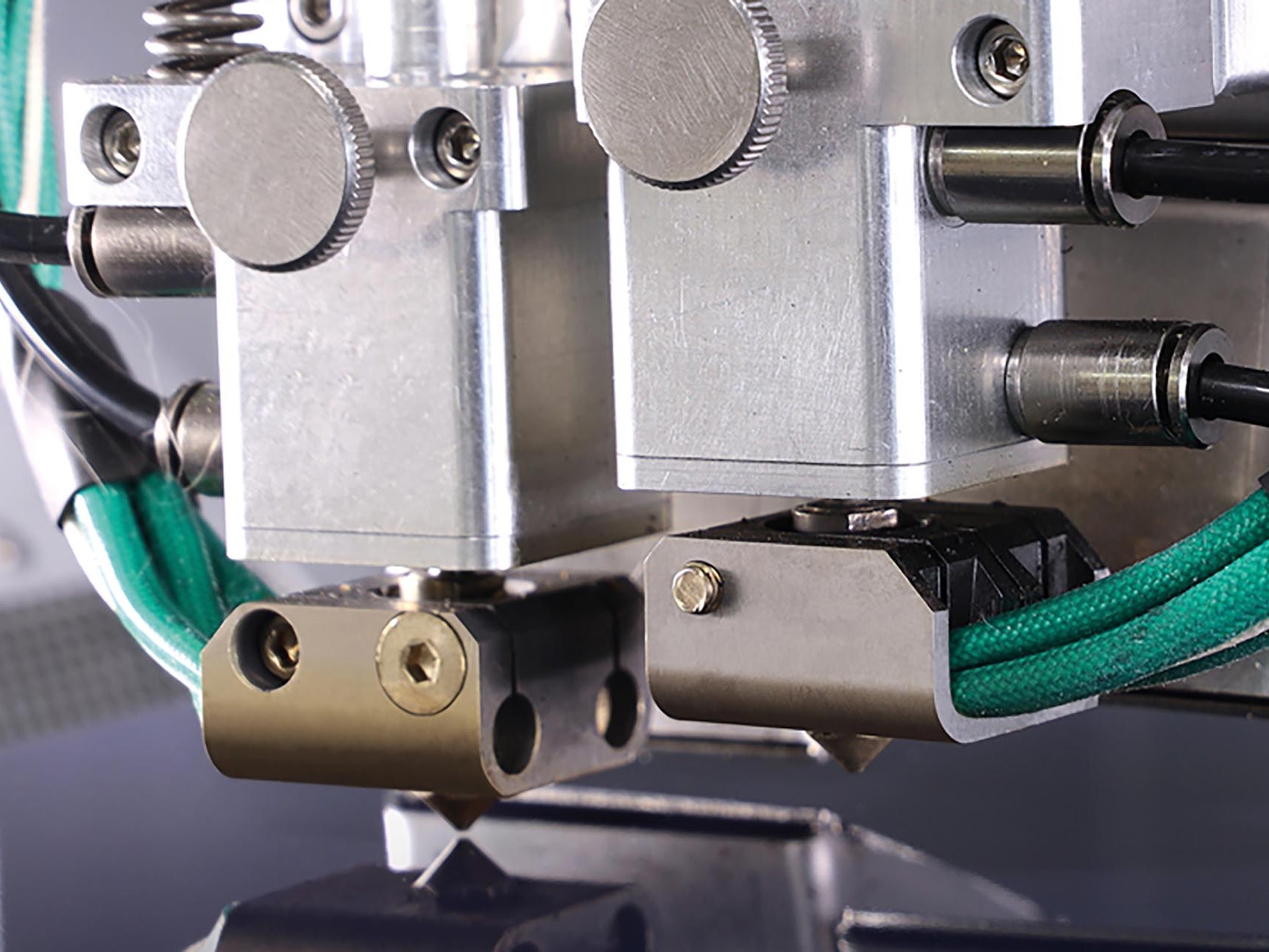

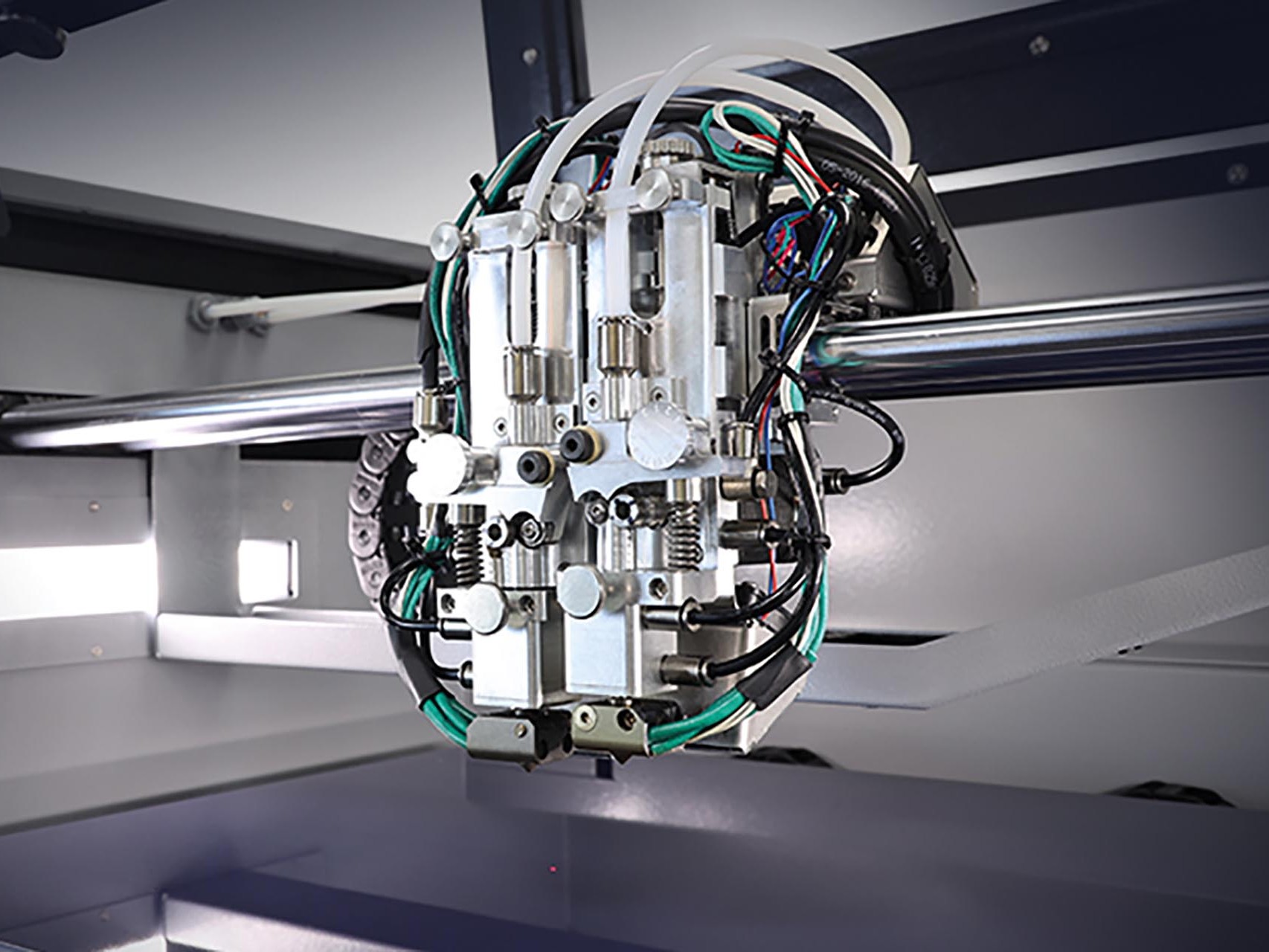

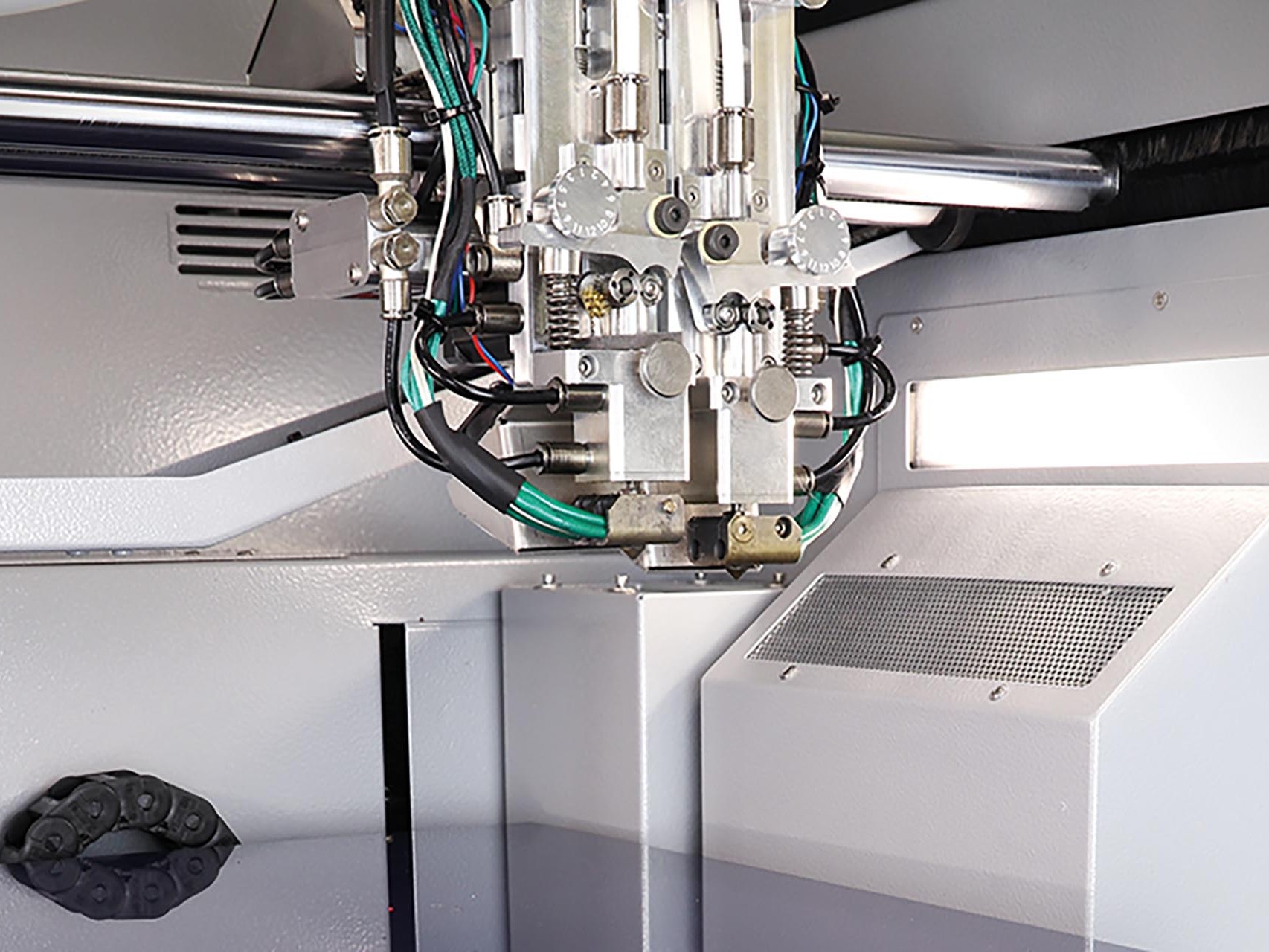

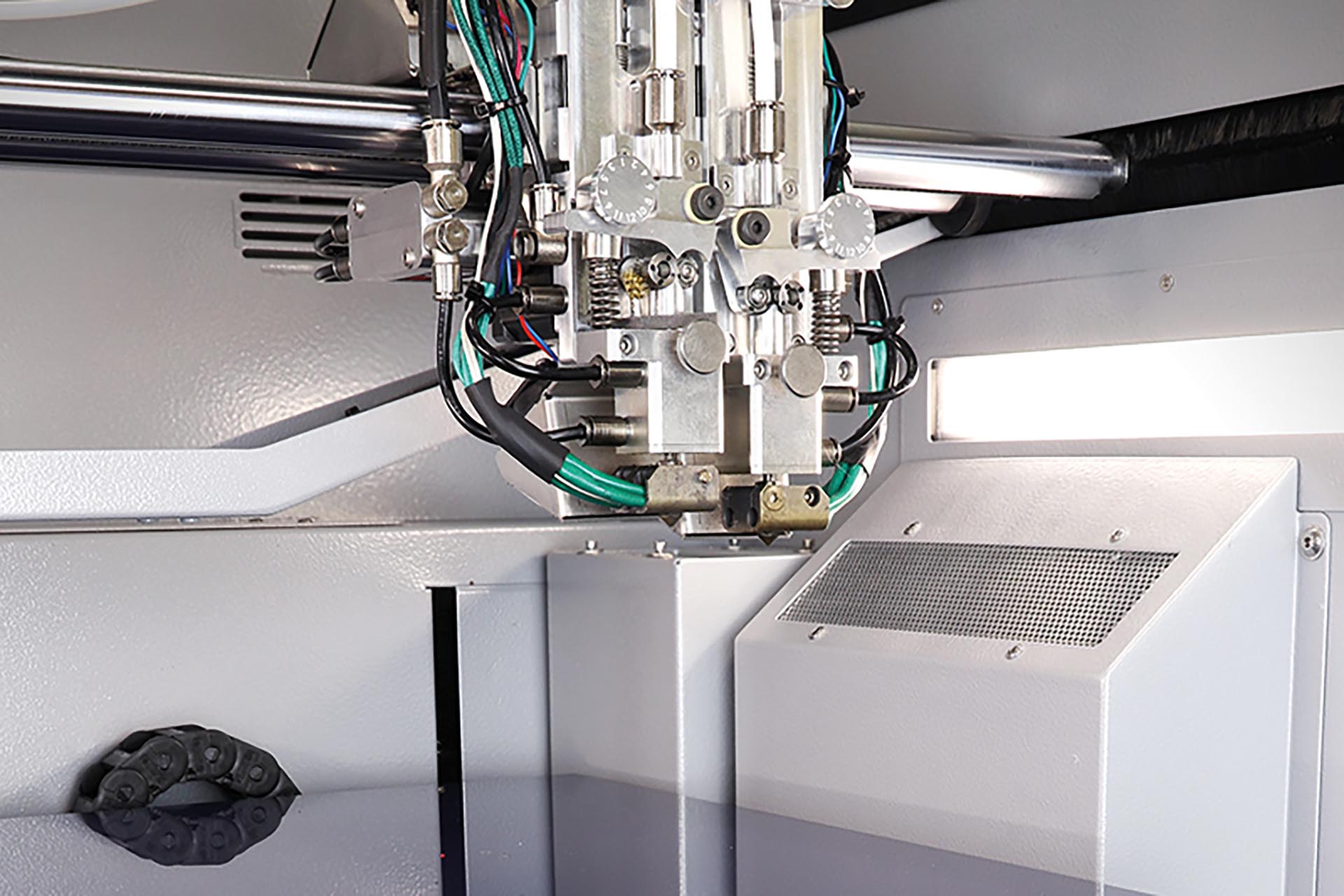

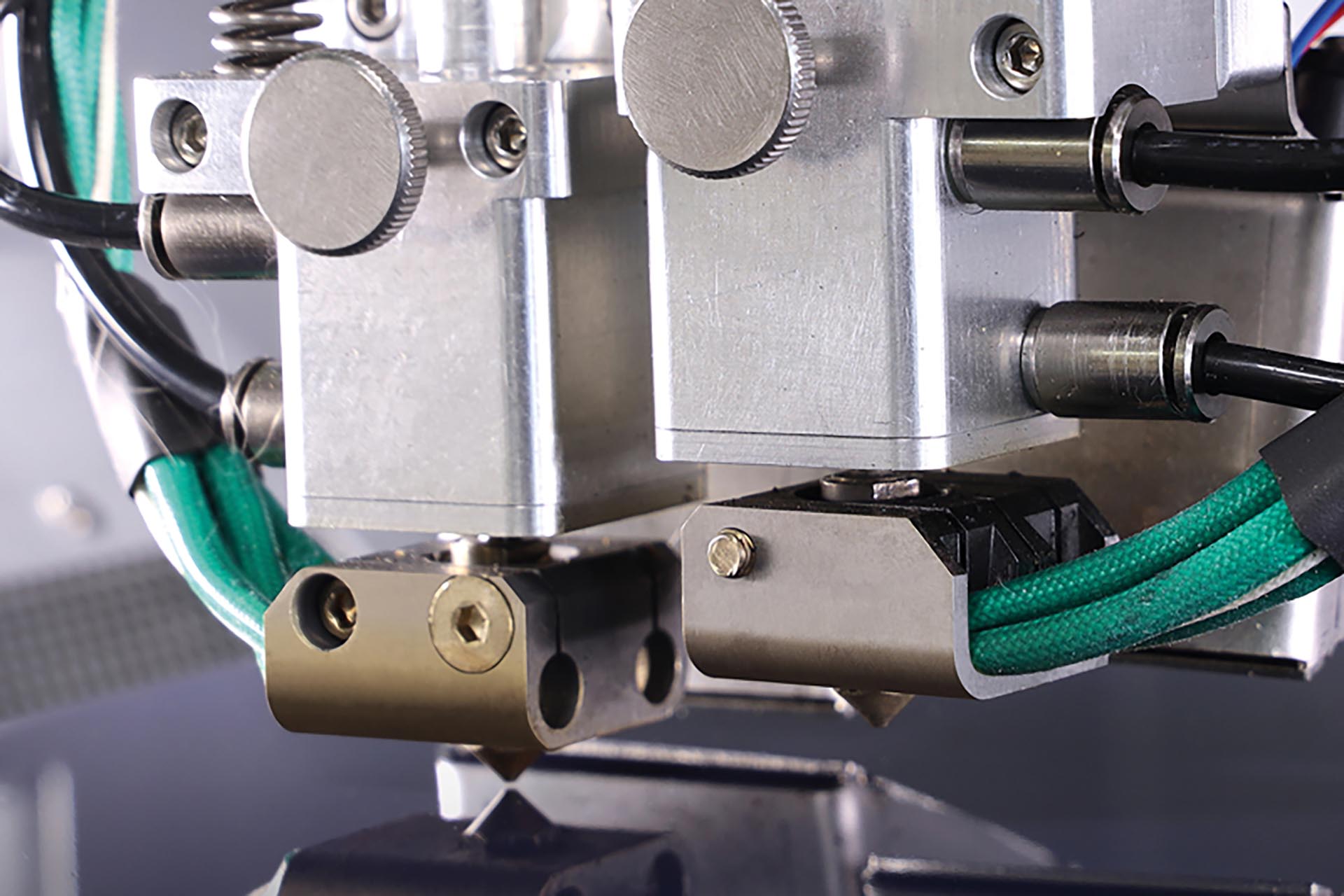

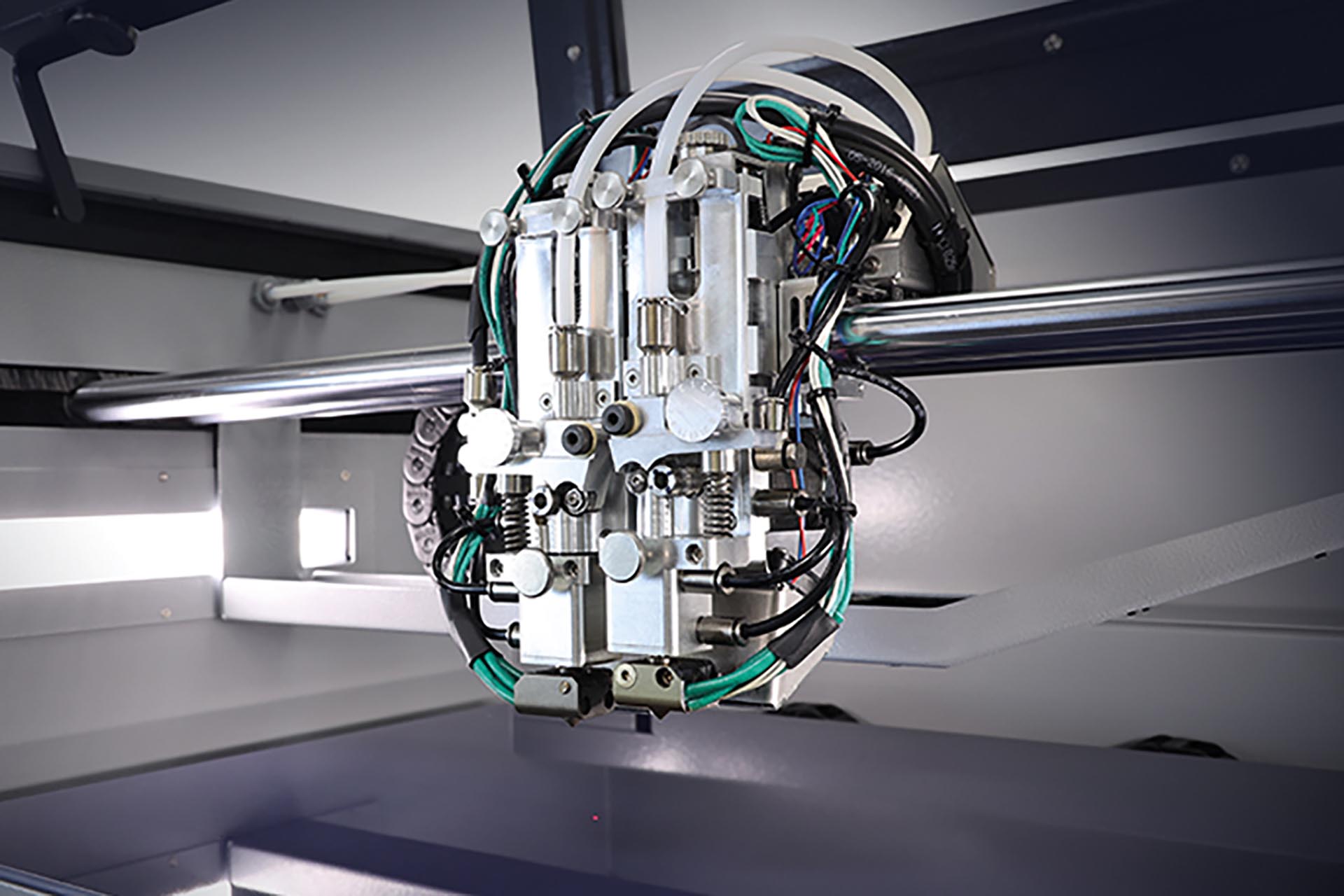

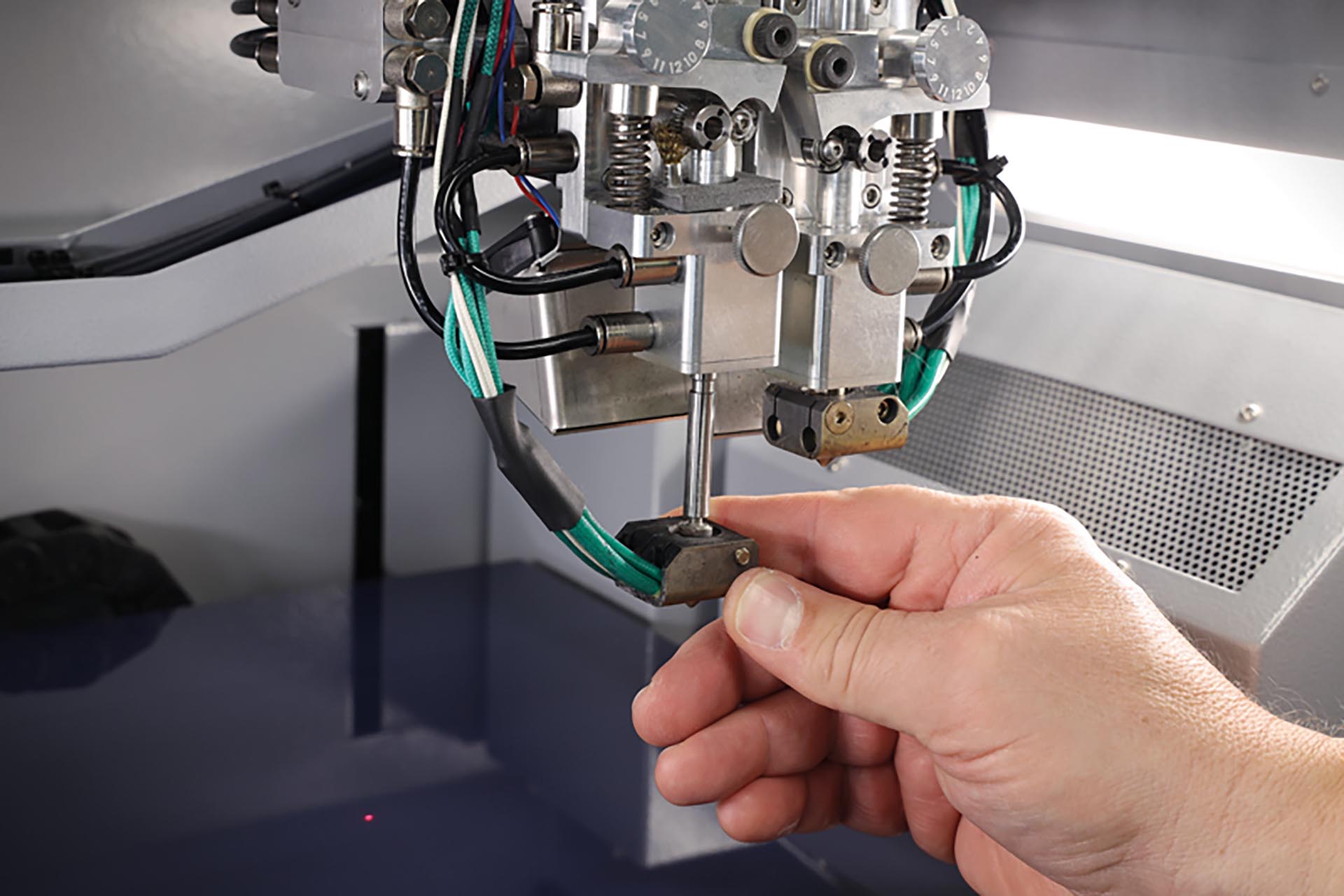

The dual-lift function increases process reliability. The upward movement of the non-extruding print head prevents collisions and material contamination.

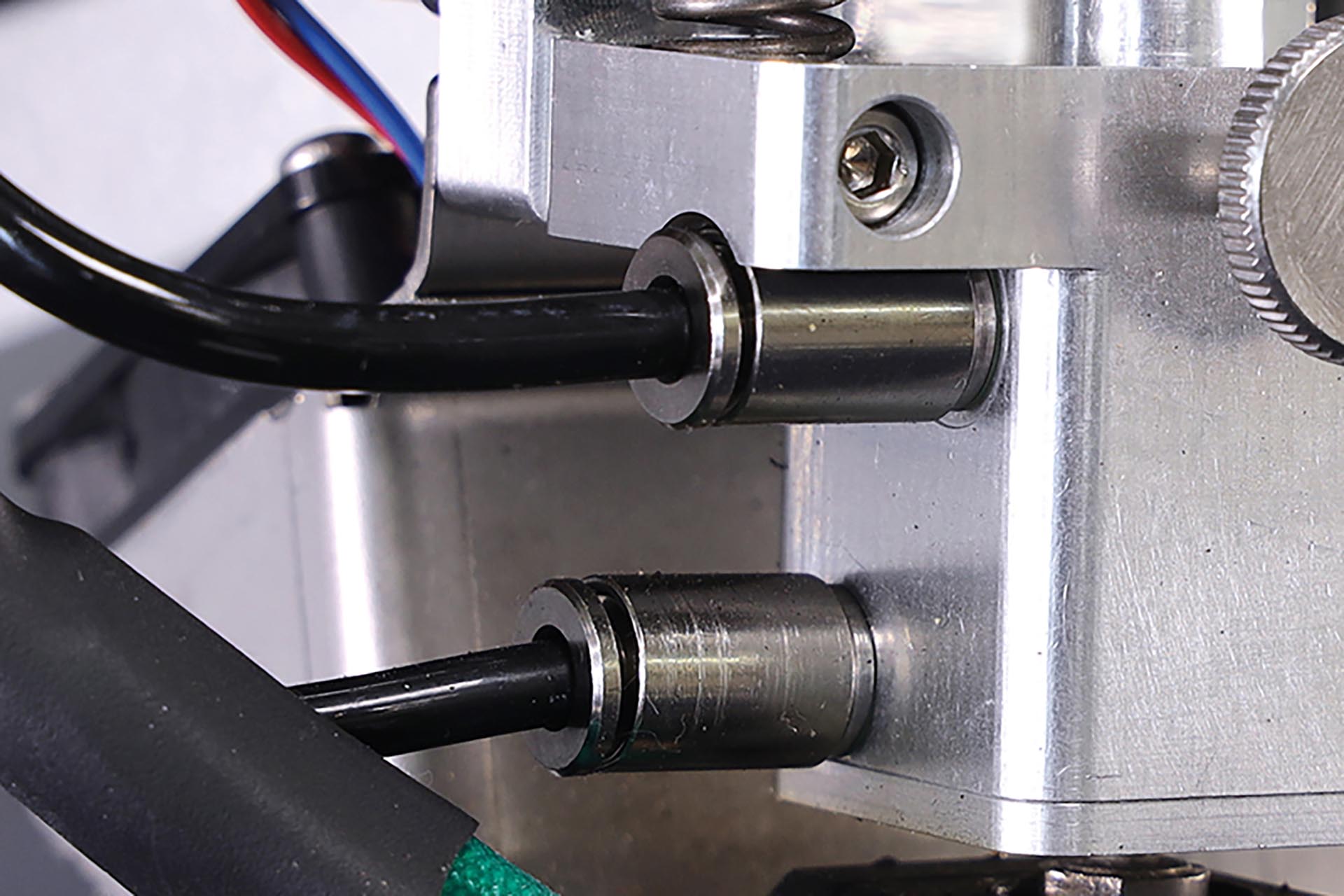

Direct Drive ensures a printing process without interruption in the material supply and, together with the SmartTrack intelligent filament tracking system, guarantees maximum process reliability in additive manufacturing.

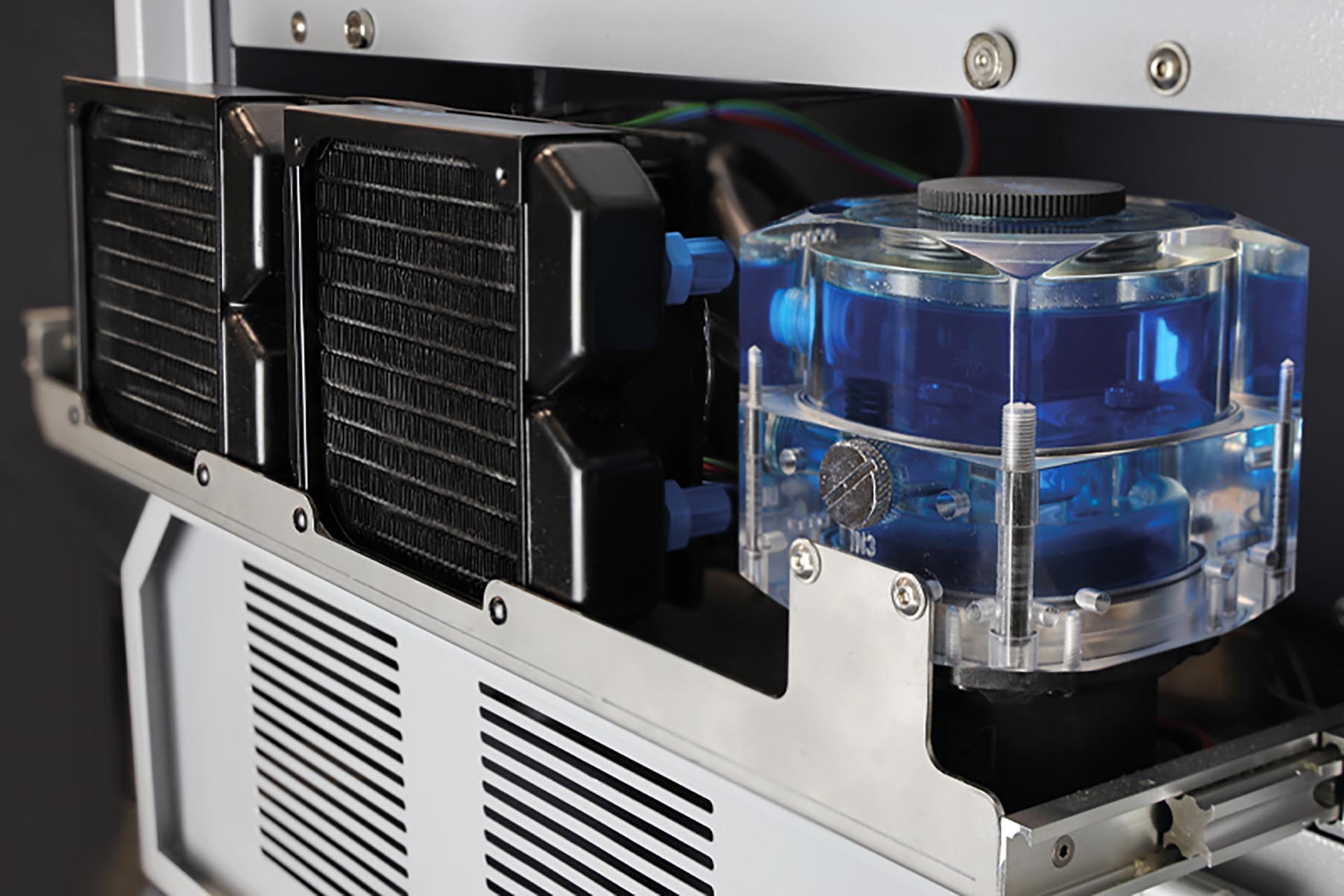

The professional cooling concept of the x500eco ensures optimum temperature control of all components during the printing process.

The x500eco can be operated intuitively via the 7-inch touchscreen. The comprehensive safety concept enables, among other things, controlled and safe intervention in the system while the process is running.

Technical data

- Print space*: (X/Y/Z) 500 x 400 x 450 mm / 19.7 x 15.7 x 17.7 in

- Print speed*: 10 – 150 mm/s

- Traversing speed*: 10 – 300 mm/s

- Repeatability*: (X/Y) +/- 0.02 / 0.05 mm

- Layer thickness*: (min.) 0.02 mm

- Filament / nozzle diameter: 1.75 mm / 0.40 mm

- Nozzle options**: 0.25 | 0.30 | 0.35 | 0.50 | 0.60 | 0.80 mm

- Extruder type DD4 Dual Extruder with Dual Lift Extruder System (water cooled)

- Extruder temperature (max.) 400°C

- Installation temperature: 80°C

- Heating bed temperature: 150°C

- Optional equipment**: Annealing oven

- Data exchange: Stand-alone printing with highly sensitive touch display, USB stick and Ethernet

- Software: Simplify3D

- Power consumption: (max.) 2.3 kW, 20-30% in continuous operation

- Connected load*: 230 V, 16 A Ambient temperature: 15-26°C

- external dimensions (W/D/H) 1120 x 850 x 955 mm

- Weight: approx. 185 kg

- Technology: FFF (Fused Filament Fabrication)

* Utilization of full building area is only possible with primary extruder (left).

** Deviations depending on equipment/material/process

Service & Support

Would you like a personal consultation or an individual offer for this system?

With pleasure! Contact our Service & Support Team for a personal handling of your request.

Materials compatible with this system:

Nothing found.